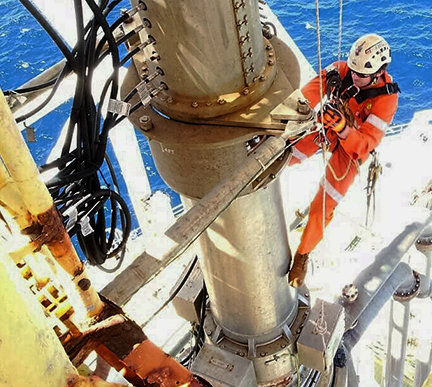

Hazardous Area

HazTech Solutions have successfully gained an impressive track record with major Oil and Gas companies in the field of Ex Hazardous Area Installation and Inspection to IEC 60079, AS/NZS 60079 and AS/NZS 3000.

This includes a number of high-profile projects as far as West Africa, Asia, Russia and Australia. It is this track record that clearly demonstrates our core capabilities available to prospective clients.

Adapting best working practice, our key personnel have the necessary experience which includes large scale projects, onsite training and managing of personnel both onshore and offshore.

We recognise that in all industries safety is critical and this will remain a key driver for all operators and their respective projects. Therefore, quality of workmanship and attention to detail is paramount and HazTech’s qualified personnel meet necessary International Standards (IECEx).

Recognised EEHA AND IECEx CoPC training completed by HazTech personnel includes just some of the following:

|

UEE

NEEM 004B

|

Ex 003

|

Install

Ex-Equipment and Wiring Systems

|

|

UEE

NEEM 006B

|

Ex 004

|

Maintain

Equipment in Hazardous Areas

|

|

UEE

NEEM 009B

|

Ex 006

|

Test

Installations in Hazardous Areas

|

|

UEE

NEEM 010B

|

Ex 007

|

Perform visual & close

inspection of Hazardous Installations

|

|

UEE

NEEM 011B

|

Ex 008

|

Perform detailed inspection

of Hazardous Installations

|

From an initial sample inspection through to delivery of a complete tag database, our considerable experience assists operators alleviate common problems that may arise during inspections, thereby minimising disruption during Construction and Commissioning Phases, ultimately reducing the requirement for re-inspections.

With Ex Inspections a statutory requirement, HazTech’s personnel provide:

- Complete hazardous area inspection documentation and dossier

- Marked drawings and layouts

- Datasheet

- Certificate of Conformity

- Hazardous Area Layout drawings

- Complete Tag Database

With the additional ability to categorise the overall work scope, we can further assist operators with the added benefit of training and ongoing support.

We can assist clients achieve their aim of a legislation compliant installation, complete with supporting documentation provided in a hazardous area report that meets the necessary industry requirements.

If it is hands-on experience supported by industry recognised international qualifications, then HazTech delivers every time.